DeMeet

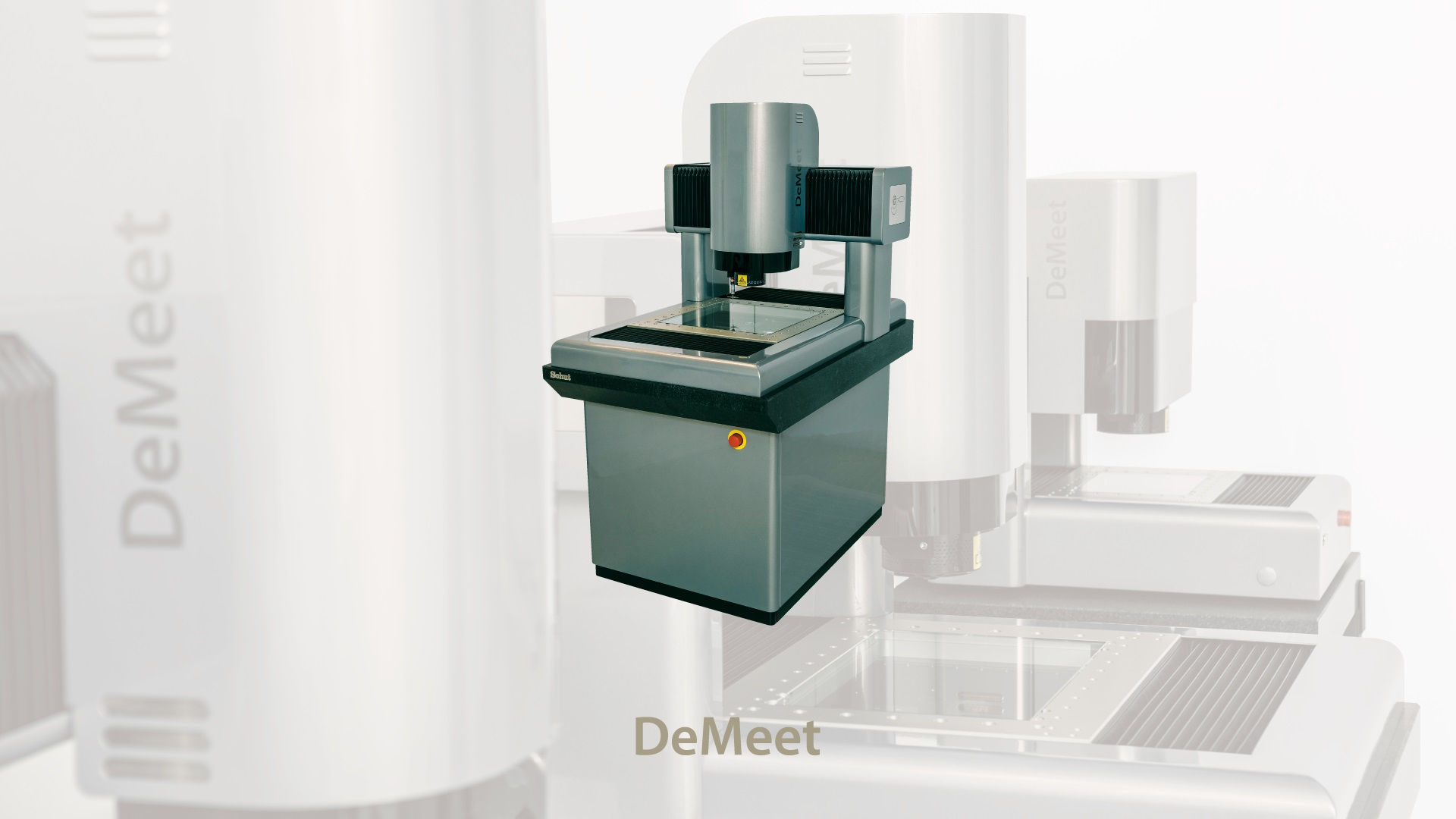

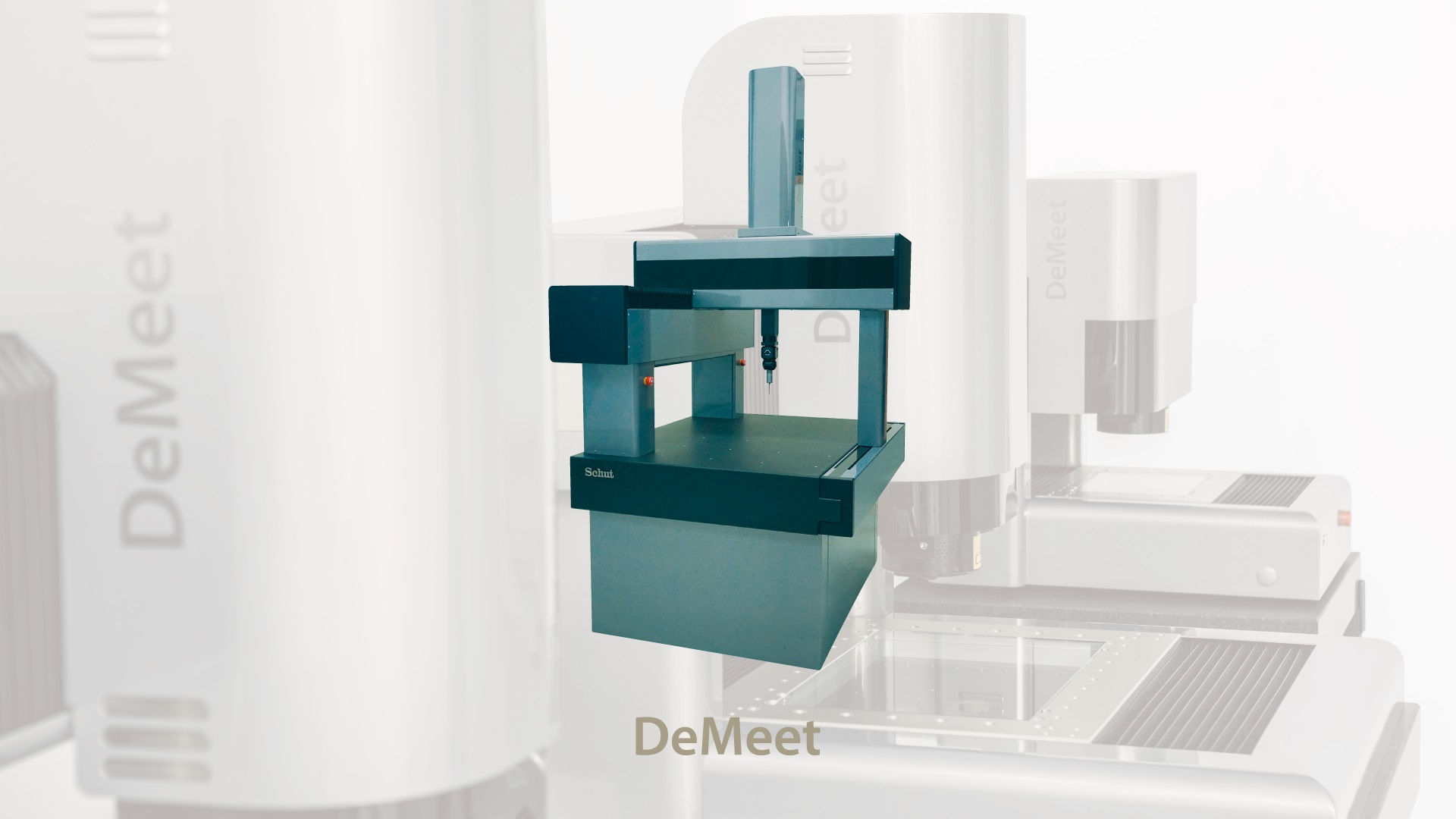

The DeMeet 3D CNC coordinate measuring machines provide automatic, user-independent quality control with measuring results traceable to the international length standard. The DeMeet measuring machines are available in Video (optical) and Combo model (multi-sensor for combined video and touch probe measurements). The DeMeet multi-sensor measuring machines are an excellent all-in-one alternative to other measuring devices for example a measuring microscope, profile projector and height gauge. With an excellent price-performance ratio the DeMeet measuring machines enable high precision quality control in measuring laboratories as well as on the production floor. Applications of optical and multi-sensor measuring are among others in the precision engineering, medical, plastics and electronics industry.

Video and Combo measuring machines for general quality control with a market-matched measuring range. The DeMeet-220 is developed as a personal measuring machine with a desktop design. For the inspection of larger products or for batch measurements the DeMeet-400 series are allround measuring machines, with the DeMeet-705 at the top of the range.

DeMeet PDF

Video and Combo measuring machines for general quality control with a market-matched measuring range. The DeMeet-220 is developed as a personal measuring machine with a desktop design. For the inspection of larger products or for batch measurements the DeMeet-400 series are allround measuring machines, with the DeMeet-705 at the top of the range.

DeMeet PDF

Optics

Optical measurements

Optical measurements are performed using the camera system, optics and adjustable illumination. Due to the non-contact nature of the measurements there is no risk of product deformation. Optical measuring is very suitable for products with fine structures and contact sensitive products. Another advantage of optical measurements is that edge information can be defined directly with high density of measuring points. Within the field of view of the DeMeet a very high accuracy can be achieved.

Optical system

A combination of high quality telecentric optics and DeMeet Sony sensor camera is integrated for a clear image with an excellent contrast and a high resolution. In combination with the image processing functionality of the DeMeet, this results in highly accurate measurements. Telecentric optics are supplied as a standard to avoid perspective image distortion around the center of the field of view. The DeMeet is either equipped with Nikon or Leica-Design optics with a large working distance for a brilliant image with high contrast providing optimal edge detection. The lenses with various magnifications from 1x to 10x are available and can be exchanged during a measuring run, generating a range in display magnification from 40x to 400x.

Combo preparation

With the option 'prepared for Combo' a Video machine can be upgraded on a later date to a multi-sensor measuring machine for combined video (optical) and touch probe (contact) measurements. For upgrading of a Combo prepared machine on a later date a Combo upgrade pack can be ordered.

Optical measurements are performed using the camera system, optics and adjustable illumination. Due to the non-contact nature of the measurements there is no risk of product deformation. Optical measuring is very suitable for products with fine structures and contact sensitive products. Another advantage of optical measurements is that edge information can be defined directly with high density of measuring points. Within the field of view of the DeMeet a very high accuracy can be achieved.

Optical system

A combination of high quality telecentric optics and DeMeet Sony sensor camera is integrated for a clear image with an excellent contrast and a high resolution. In combination with the image processing functionality of the DeMeet, this results in highly accurate measurements. Telecentric optics are supplied as a standard to avoid perspective image distortion around the center of the field of view. The DeMeet is either equipped with Nikon or Leica-Design optics with a large working distance for a brilliant image with high contrast providing optimal edge detection. The lenses with various magnifications from 1x to 10x are available and can be exchanged during a measuring run, generating a range in display magnification from 40x to 400x.

Combo preparation

With the option 'prepared for Combo' a Video machine can be upgraded on a later date to a multi-sensor measuring machine for combined video (optical) and touch probe (contact) measurements. For upgrading of a Combo prepared machine on a later date a Combo upgrade pack can be ordered.

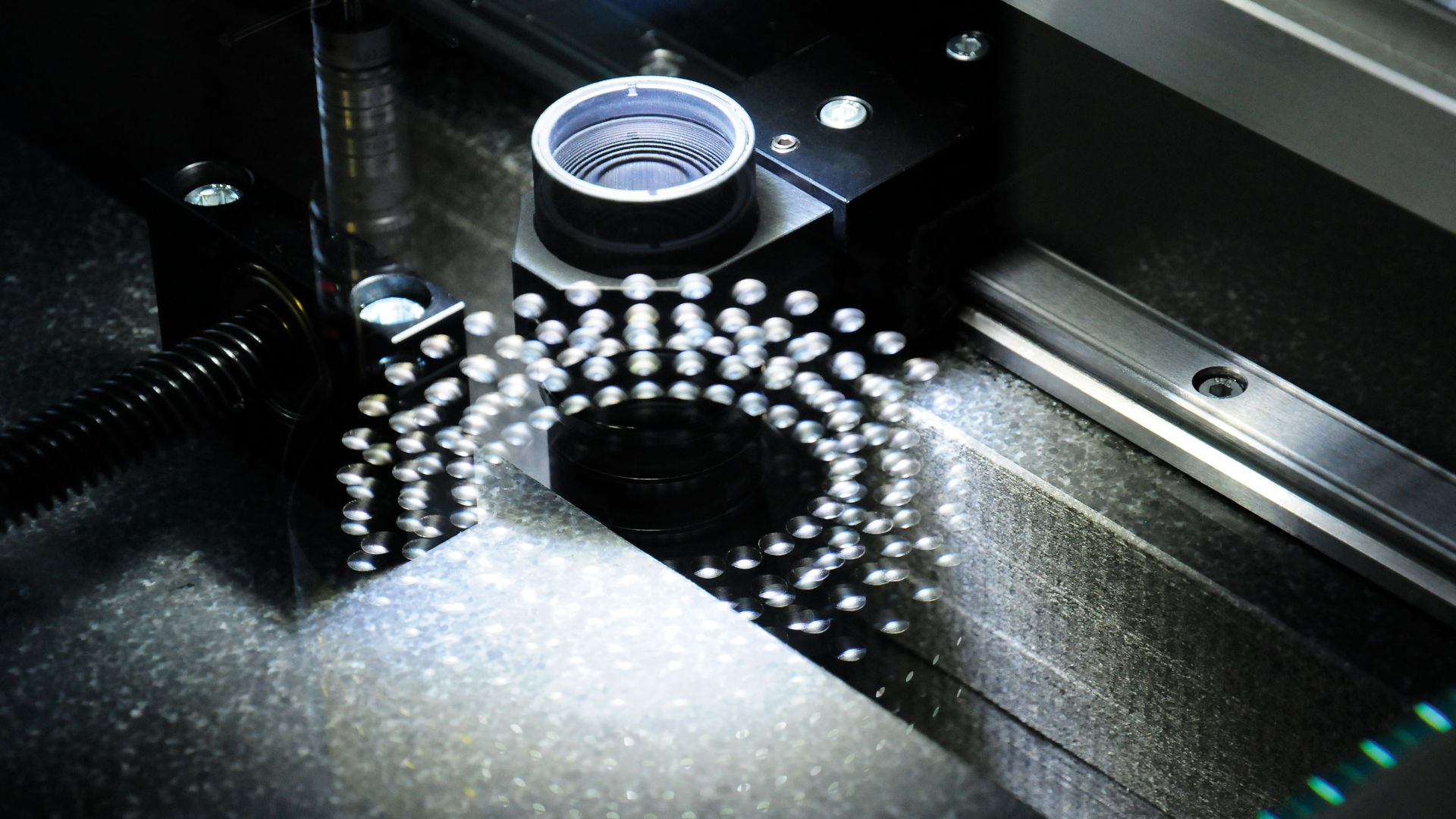

Illumination

Illumination is essential for accurate measurements. The DeMeet is standard equipped with LED based illumination (backlight, coaxial light and segmented ring light).

A ring light consisting of a 3 rings, 16 segments and 48 cells LED pattern, that can be controlled per individual ring, segment and cell, is standard supplied for optimal light configuration. The ring light can be set in intensity and angle to achieve the best contrast with clearly defined edges.

The backlight is transmitted from below and is used to highlight the profile of the edges. Coaxial lighting can be used for illumination inside deep located structures. The LED based backlight and coaxial light can be adjusted in intensity.

The configuration of the illumination is automatically controlled during a CNC measuring run. A coaxial laser pointer assists navigation during creation of a measuring program.

A ring light consisting of a 3 rings, 16 segments and 48 cells LED pattern, that can be controlled per individual ring, segment and cell, is standard supplied for optimal light configuration. The ring light can be set in intensity and angle to achieve the best contrast with clearly defined edges.

The backlight is transmitted from below and is used to highlight the profile of the edges. Coaxial lighting can be used for illumination inside deep located structures. The LED based backlight and coaxial light can be adjusted in intensity.

The configuration of the illumination is automatically controlled during a CNC measuring run. A coaxial laser pointer assists navigation during creation of a measuring program.

Multi-sensor technology

The increasing miniaturization and complexity of product features results in more difficult measuring and inspection procedures. Measuring systems equipped for only optical or contact measurements are often no longer sufficient, in which case multi-sensor measuring machines are required for optimal geometrical quality control.

When measuring certain features encounters the physical limits of non-contact measurement, the DeMeet video machines can be additionally equipped with a touch probe system (contact measuring system).

With the DeMeet Combo model both optical and contact measuring principles are seamlessly integrated and measurements can be performed by the optical and the probing system within one measuring run and even within one feature. Touch probe measurements can also be useful to create a complex 3D product alignment.

Probe modules and styli

Standard a Renishaw TP20 system with a 5-way stylus configuration is supplied. On request various probe modules, systems and stylus configurations are available. Multiple probe modules can be used to leave the stylus configuration on the module to achieve a shorter set-up time for measurements requiring other stylus configurations.

In addition to the standard touch probe system, an optional stylus change rack (automatic probe configuration change) can be utilized. With the stylus change rack probe modules can automatically be exchanged within one measuring run.

When measuring certain features encounters the physical limits of non-contact measurement, the DeMeet video machines can be additionally equipped with a touch probe system (contact measuring system).

With the DeMeet Combo model both optical and contact measuring principles are seamlessly integrated and measurements can be performed by the optical and the probing system within one measuring run and even within one feature. Touch probe measurements can also be useful to create a complex 3D product alignment.

Probe modules and styli

Standard a Renishaw TP20 system with a 5-way stylus configuration is supplied. On request various probe modules, systems and stylus configurations are available. Multiple probe modules can be used to leave the stylus configuration on the module to achieve a shorter set-up time for measurements requiring other stylus configurations.

In addition to the standard touch probe system, an optional stylus change rack (automatic probe configuration change) can be utilized. With the stylus change rack probe modules can automatically be exchanged within one measuring run.

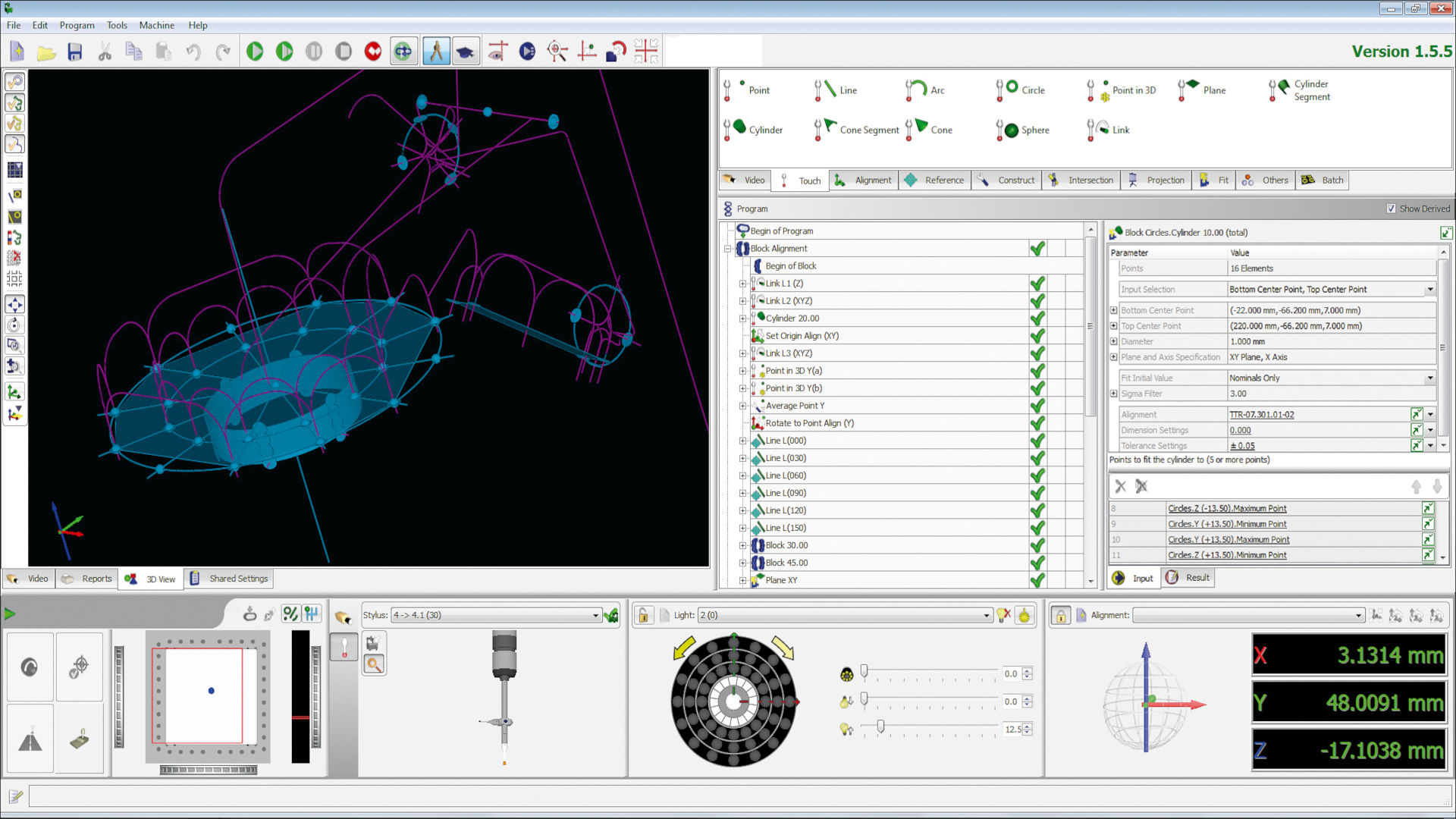

Approve for DeMeet Multi-sensor measuring software

Approve for DeMeet is a true multi-sensor software package, where the difference in sensor origin of the measuring input is limited to only the necessary.

All the measuring results of video and touch probe can be displayed, reported, exported and used in constructs together, and are dynamically updated. The measuring results can also be displayed together in a 3D view.

Approve for DeMeet is designed to be a user-friendly software package, but is flexible and very elaborate to measure many products.

All the measuring results of video and touch probe can be displayed, reported, exported and used in constructs together, and are dynamically updated. The measuring results can also be displayed together in a 3D view.

Approve for DeMeet is designed to be a user-friendly software package, but is flexible and very elaborate to measure many products.

3D Movements

The 3D motor controller in Approve for DeMeet makes blended, smooth moves which makes the DeMeet run more fluent and faster. The DeMeet also moves during video image processing and other calculations, shortening the measuring time considerably. To eliminate hysteresis, and therefore improving accuracy, an approach direction and distance can be set for video measurements. Pretouch and average touch can be set for touch measurements.

Measurements

For video measurements our proprietary image processing algorithms were developed, which are completely different from algorithms used by competing products. The edge find algorithm finds complete curves instead of separate points, the interpolation of the pixels is virtually infinite and very accurate. Video targets larger than one field of view can be measured in one program step, and are automatically split into more images and combined for the fitted result. The illumination for video measurements can be set and changed using a graphical control for backlight, coaxial light and ring light.

For touch measurements it is normal that the targets are defined in 3D, but now this is also the case for video measurements. Features (like a circle) can be measured properly even if they are not parallel to the camera (optical) plane. The graphical touch probe configuration editor allows for building a custom configuration for a specific measurement by using an extensive touch probe library. Settings can be defined and shared between measuring steps which greatly reduces the complexity of a measuring program.

For touch measurements it is normal that the targets are defined in 3D, but now this is also the case for video measurements. Features (like a circle) can be measured properly even if they are not parallel to the camera (optical) plane. The graphical touch probe configuration editor allows for building a custom configuration for a specific measurement by using an extensive touch probe library. Settings can be defined and shared between measuring steps which greatly reduces the complexity of a measuring program.

Measuring Program

A measuring program in Approve for DeMeet is a graphical program consisting of simple program steps. Program steps can be changed, added, copied, moved and removed very easily, inputs of a program step can be easily changed or linked to other results by using drag-and-drop. A program can be verified by running it step by step, even a single program step can be run for verification. After running a program step an icon appears behind it to indicate its status.

Results, Report and Export

Results from measurements and calculations (constructs, fits, etc.) as well as from other program steps can be added to an export or report and saved or printed as PDF or CSV file for further analysis. If tolerances are used for a result a graphical tolerance bar is shown. Results and reports can be automatically printed or exported at the end of a measuring program run.

PTB software evaluation

Evaluation software for coordinate measuring machines.

The accuracy of the evaluation software was verified by comparing the results obtained from the software with reference results supplied by the PTB (Physikalisch-Technische Bundesanstalt, Braunschweig, Germany).

The Approve for DeMeet software has been placed in the class of the smallest deviations.

PTB Testreport PDF

The accuracy of the evaluation software was verified by comparing the results obtained from the software with reference results supplied by the PTB (Physikalisch-Technische Bundesanstalt, Braunschweig, Germany).

The Approve for DeMeet software has been placed in the class of the smallest deviations.

PTB Testreport PDF

Design and quality

The application of quality components made by Schut and by well-known, specialized manufacturers ensures excellent performance and high accurate measurements. With the new design of the DeMeet measuring machine series no concessions have been made to accuracy and reliability. The new visually screwless cover design provides a better protection in the production environment and is highlighted with nickel-plated aluminum details which can be personalized. The open design of the DeMeet allows for easy operation and loading of the machine from all sides.

The accuracy of the DeMeet measuring machines is guaranteed by a CAA 3D correction model (Computer-Aided Accuracy, error compensation). Machine construction

The DeMeet 3D CNC coordinate measuring machines are designed with a proven fixed bridge construction and moveable measuring table for high accuracy and accessibility. The completely covered drive system and integrated damping make the DeMeet machines very suitable for inline measuring on the production floor.

The construction is a granite base plate with accuracy grade according to DIN 876/00, placed on well positioned shock absorbing points and resting on a welded base frame (for the DeMeet-220 the base plate is flat grinded cast iron). The XYZ base structure for the THK precision preloaded caged ball linear guides is made from extremely tension relieved, flat grinded cast iron, as the basis for a mechanical accurate construction. The axis drive system consists of Faulhaber high torque DC servo motors, TFE coated Kerk lead screws and Renishaw TONIC optical linear encoders with low sub-divisional error. The measuring table is made of tension relieved, wear-resistant, hard anodized aluminum, or optionally nickel-plated steel, with a mounting hole pattern for product fixtures and a flat aligned glass plate. The video model consists of a DeMeet camera with a Sony sensor and a telecentric optical system. In addition to the optical system the Combo model is equipped with a Renishaw touch probe system.

The accuracy of the DeMeet measuring machines is guaranteed by a CAA 3D correction model (Computer-Aided Accuracy, error compensation). Machine construction

The DeMeet 3D CNC coordinate measuring machines are designed with a proven fixed bridge construction and moveable measuring table for high accuracy and accessibility. The completely covered drive system and integrated damping make the DeMeet machines very suitable for inline measuring on the production floor.

The construction is a granite base plate with accuracy grade according to DIN 876/00, placed on well positioned shock absorbing points and resting on a welded base frame (for the DeMeet-220 the base plate is flat grinded cast iron). The XYZ base structure for the THK precision preloaded caged ball linear guides is made from extremely tension relieved, flat grinded cast iron, as the basis for a mechanical accurate construction. The axis drive system consists of Faulhaber high torque DC servo motors, TFE coated Kerk lead screws and Renishaw TONIC optical linear encoders with low sub-divisional error. The measuring table is made of tension relieved, wear-resistant, hard anodized aluminum, or optionally nickel-plated steel, with a mounting hole pattern for product fixtures and a flat aligned glass plate. The video model consists of a DeMeet camera with a Sony sensor and a telecentric optical system. In addition to the optical system the Combo model is equipped with a Renishaw touch probe system.

Technical specifications

| General | Video model | Combo model |

|---|---|---|

| Video system | DeMeet Sony sensor camera | |

| Nikon telecentric lenses | 3,0x (1,0x, 5,0x and 10,0x optional) | |

| Leica-design telecentric lenses | 2,0x (1,0x, 5,0x and 10,0x optional) | |

| Mitutoyo telecentric lenses | 3,0x (1,0x, 5,0x and 10,0x optional) | |

| Ring light | 3 rings, 16 segments and 48 cells (adjustable) | |

| Backlight and coaxial light | Adjustable | |

| Probe system | - | Renishaw TP20 |

| Construction | Fixed bridge with granite base plate (DIN 876/00) | |

| Structure | Extremely tension relieved, flat grinded cast iron | |

| Measuring table | Tension relieved, nickel-plated steel | |

| Linear guides | THK linear guides | |

| Linear encoders | Renishaw TONIC linear encoders | |

| Drive system | Faulhaber DC servo motors | |

| Operating mode | motorized joystick / CNC | |

| DeMeet-220 | Video model | Combo model |

| Measuring range (mm) | X 220, Y 150, Z 100 | |

| Dimensions (mm) | W 520, L 700, H 615 | |

| Weight (kg) | 110 | |

| Measuring table (mm) | X 357, Y 264 | |

| Max. load (kg) | 20 | |

| DeMeet-400 | Video model | Combo model |

| Measuring range (mm) | X 400, Y 250, Z 200 | |

| Dimensions (mm) | W 870, L 930, H 1570 | |

| Weight (kg) | 530 | |

| Measuring table (mm) | X 560, Y 426 | |

| Max. load (kg) | 50 | |

| DeMeet-404 | Video model | Combo model |

| Measuring range (mm) | X 400, Y 400, Z 200 | |

| Dimensions (mm) | W 870, L 1245, H 1580 | |

| Weight (kg) | 700 | |

| Measuring table (mm) | X 560, Y 584 | |

| Max. load (kg) | 20 | |

| DeMeet-443 | Video model | Combo model |

| Measuring range (mm) | X 400, Y 400, Z 300 | |

| Dimensions (mm) | W 870, L 1245, H 1785 | |

| Weight (kg) | 720 | |

| Measuring table (mm) | X 560, Y 584 | |

| Max. load (kg) | 50 | |

| DeMeet-705 | Video model | Combo model |

| Measuring range (mm) | X 700, Y 500, Z 300 | |

| Dimensions (mm) | W 1520, L 1550, H 1820 | |

| Weight (kg) | 1400 | |

| Measuring table (mm) | X = 930, Y = 704 | |

| Max. load (kg) | 60 | |

| Measuring specifications | Video model | Combo model |

| Resolution (µm) | 0,1 | |

| Accuracy standard (µm) | X/Y/Z 3,9 + L/150 | |

| (L in mm) | XY 4,5 + L/150 | XYZ 4,9 + L/150 |

| Accuracy high (µm) | X/Y/Z 2,9 + L/200 | |

| (L in mm) | XY 3,5 + L/200 | XYZ 3,9 + L/200 |

| Accuracy optional (µm) | X/Y/Z 1,9 + L/250 | |

| (L in mm) | XY 2,5 + L/250 | XYZ 2,9 + L/250 |

| Travel speed max. (mm/s) | X/Y 250, Z 55 | |

| Acceleration max. (mm/s^2) | X/Y/Z 500 | |

| Power requirements | Video model | Combo model |

| Voltage (V) | 90 - 120, 210 - 240 (50 - 60 Hz) | |

| Power (VA) | 400 | |

| Environmental conditions | Video model | Combo model |

| Operating temperature (°C) | 15-35 | |

| Measuring temperature (°C) | 20 ± 0,5 | |

| Humidity (%) | 40 - 70 (no condensation) | |

| Computer | Video model | Combo model |

| Minimum system requirements | CPU: Intel i3 (or AMD equivalent) or higher. Internal Memory: 4 GB RAM or more. Video Card: PCI-e display adapter supporting OpenGL with pixelbuffer extension (recommended: nVidia Quadro P400 or higher). Recommended screen resolution:1920x1080 (Full-HD). USB port to connect the dongle. Serial port to connect the DeMeet 3D CNC measuring machine. Only 'real' serial-ports are supported, USB-to-Serial converters are not supported. PCI-e slot for SGM15400 framegrabber (video only). | |

| Operating system | Windows 10 | |